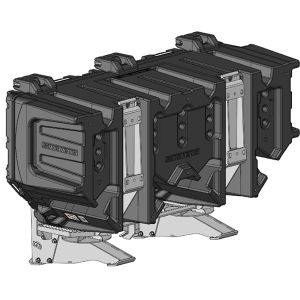

SiteTote® & Virnig Spreader System: Product Gallery & Specifications

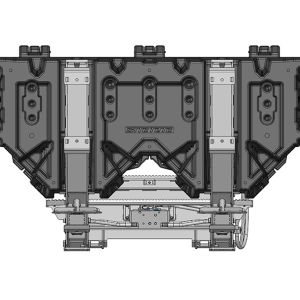

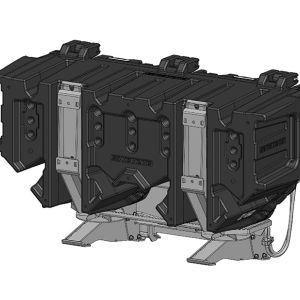

The SiteTote system revolutionizes traditional snow and ice management by adopting a strategy of on-site preparedness. This proactive approach involves staging salt material directly at job locations using the SiteTote storage unit, eliminating the logistical delays inherent in relying on centralized salt trucks. The system integrates the SiteTote with the Virnig Salt Spreader, a specialized, front-mounted attachment designed to work seamlessly with existing equipment like skid loaders or compact wheel loaders via a standard quick-attach coupler. This allows current plowing staff to handle salting operations without needing dedicated truck drivers, resulting in significant labor cost reduction and maximizing the efficiency of your workforce.

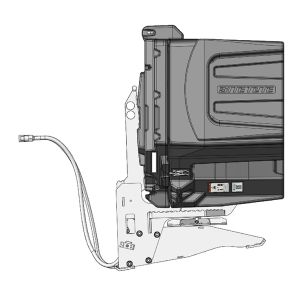

A primary operational advantage of this decentralized system is the dramatic improvement in response times; staff can report directly to job sites near their residences and begin work immediately. Furthermore, the system offers substantial cost savings by eliminating costly salt truck routes and reducing fuel consumption, while the on-site equipment use can lower commercial driver insurance costs. The spreading itself is highly efficient: the Virnig unit features low, dual variable-speed spinners for a precise, even spread, capable of casting material under parked vehicles. Operating solely off the machine's standard hydraulic auxiliary couplers, the spreader requires no complex wiring or cab controllers, ensuring any compatible machine can be used at any time.

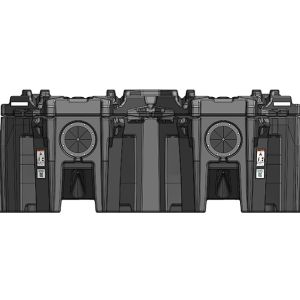

In terms of capacity, each SiteTote unit holds a substantial 1,600 pounds (0.8 tons) of rock salt. This material can be easily managed and refilled with a standard skid loader bucket due to the unit's low fill height. At a recommended average application rate, a single SiteTote load offers an impressive coverage area of approximately 228,000 square feet (5.2 acres). This precise, on-site control not only minimizes salt waste—providing an environmentally friendly solution that avoids unsightly tarps and bins—but also allows for quick switching between different specified products using dedicated SiteTote units, making it ideal for managing diverse surfaces from parking structures to brick pavers. The flexibility and cost-saving potential of this approach have been proven by companies replacing numerous salt truck routes with the SiteTote system.